Linear motors have attracted extensive attention and research in the automation industry in recent years. A linear motor is a motor that can directly generate linear motion, without any mechanical conversion device, and can directly convert electrical energy into mechanical energy for linear motion. Due to its high efficiency and precision, this new type of drive gradually replaces traditional rotating motors in automated production systems and high-precision equipment.

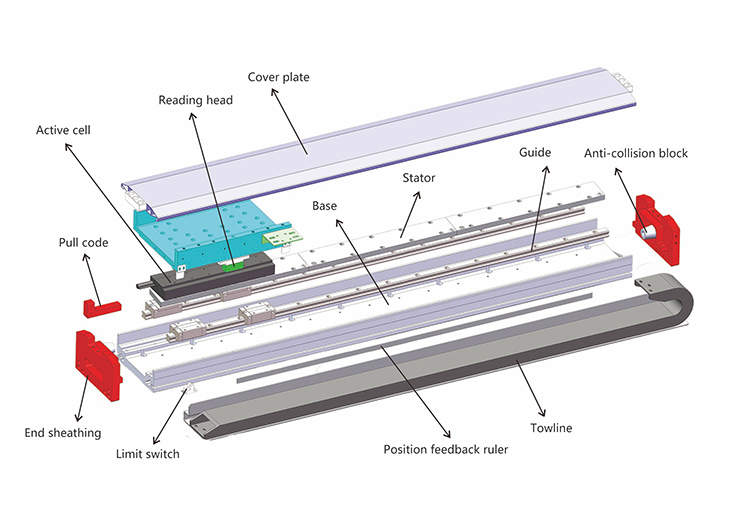

explosion diagram of LNP series linear motor

A major advantage of linear motors is their simplicity and reliability. Because the linear motion is generated directly, there is no need for conversion devices such as gears, belts, and lead screws, which greatly reduces friction and backlash in the mechanical stroke, and improves motion accuracy and response speed. At the same time, this design also greatly reduces the maintenance cost and failure rate of the equipment.

Second, linear motors have high motion accuracy and speed. Conventional rotary motors tend to lose accuracy when converting to linear motion due to friction and wear on the conversion device. Linear motors can achieve precise position control at the micron level, and can even reach nanometer level precision, making it widely used in high-precision equipment such as semiconductor manufacturing, medical equipment, precision machining and other fields.

Linear motors are also highly dynamic and efficient. Because it does not require a mechanical conversion device and reduces energy loss during motion, the linear motor is superior to the traditional rotary motor in terms of dynamic response and energy conversion efficiency.

However, although linear motors have many advantages, their high manufacturing costs limit their wide application in some price-sensitive application scenarios. However, with the advancement of technology and the reduction of cost, it is expected that linear motors will be applied in more fields.

In general, linear motors have begun to replace traditional rotary motors in some high-precision and high-efficiency automated production systems due to their simple structure, stability, reliability, high precision, and high efficiency. In the future, with the development of technology, linear motors may become the new standard in the automation industry.

Among the global linear motor manufacturers, TPA Robot is one of the leading manufacturers, and the LNP ironless linear motor developed by it is very popular in the industry.

The LNP series direct drive linear motor was independently developed by TPA ROBOT in 2016. LNP series allows automation equipment manufacturers to use flexible and easy-to-integrate direct drive linear motor to form high-performance, reliable, sensitive, and precise motion actuator stages.

TPA Robot 2nd Generation Linear Motor

Since the LNP series linear motor cancels the mechanical contact and is directly driven by the electromagnetic, the dynamic response speed of the entire closed-loop control system is greatly improved. At the same time, since there is no transmission error caused by the mechanical transmission structure, with the linear position feedback scale (such as grating ruler, magnetic grating ruler), the LNP series linear motor can achieve micron-level positioning accuracy, and the repeat positioning accuracy can reach ±1um.

Our LNP series linear motors have been updated to the second generation. LNP2 series linear motors stage are lower in height, lighter in weight and stronger in rigidity. It can be used as beams for gantry robots, lightening the load on multi-axis combined robots. It will also be combined into a high-precision linear motor motion stage, such as double XY bridge stage, double drive gantry stage, air floating stage. These linear motion stage will also be used in lithography machines, panel handling, testing machines, PCB drilling machines, high-precision laser processing equipment, gene sequencers, brain cell imagers and other medical equipment.

Post time: Aug-23-2023